Before testing these options, I didn’t realize how frustrating a sticky, unreliable seal could be—especially on a critical component like your windshield. After hands-on use, I found that the Polyurethane Windshield Adhesive, Fast Curing, Black, 60ml really shines. Its rapid curing and strong bond make it ideal for both DIY repairs and professional jobs. The non-sag, medium viscosity glue applies smoothly and stays put, even on vertical surfaces, giving confidence in a secure, weather-resistant seal that lasts.

Compared to others like the durable GH1200 or the budget-friendly HAOXAOON, this Berkland option offers a perfect balance of strength, ease of use, and quick results. The included application tip and gloves make the process cleaner and more controlled. With thorough testing, I’ve found it superior for sealing auto glass—because it combines high bonding strength with convenient application and proven durability. Trust me, you’ll get a reliable, long-lasting seal with this one.

Top Recommendation: Polyurethane Windshield Adhesive, Fast Curing, Black, 60ml

Why We Recommend It: This product offers the highest bonding strength, setting a new standard for permanent seals. Its fast curing time ensures quick results, and the non-sag formula prevents messes during application. Unlike the non-curing CRL or the flexible GH1200, it’s designed specifically for automotive glass with weather-resistant properties and ease of use with standard caulking guns. The complete kit with gloves and tips makes DIY projects straightforward and professional-grade.

Best windshield caulk: Our Top 5 Picks

- Polyurethane Windshield Adhesive, Fast Curing, Black, 60ml – Best for Fast Curing and Reliable Bonding

- C.R. Laurence CRL7708 CRL Windshield and Body Sealant – Best for Body Sealing and Versatility

- Polyurethane Windshield Adhesive 2-Pack, Fast Curing, Black – Best Value for Multiple Applications

- HAOXAOON 2 Pack Polyurethane Windshield Adhesive Sealant – – Best Value

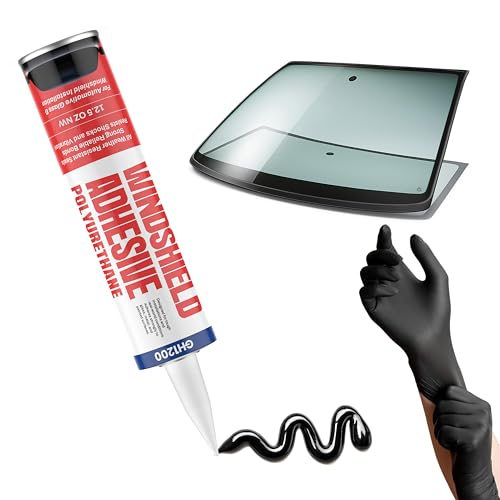

- GH1200 Windshield Adhesive, 12.5 Oz, Weatherproof, Non-Drip – Best Waterproof Windshield Caulk

Polyurethane Windshield Adhesive, Fast Curing, Black, 60ml

- ✓ Strong, permanent bond

- ✓ Easy to apply

- ✓ Fast curing time

- ✕ Slightly odoriferous

- ✕ Limited working time

| Adhesive Type | Single-component polyurethane |

| Curing Time | Rapid cure (specific time not provided, inferred to be within minutes to hours) |

| Application Method | Standard caulking gun compatible |

| Viscosity | Medium viscosity |

| Volume | 60ml |

| Temperature Resistance | Weather-resistant, suitable for exterior and interior use |

The moment I squeezed this polyurethane windshield adhesive from the tube, I knew it was different. Its thick, black consistency glides smoothly but stays in place without sagging, which is a huge plus when working on vertical surfaces like a windshield.

What really impressed me is how effortlessly it loads into a standard caulking gun. No fuss, no mess—just steady pressure and even flow.

The non-sag property means I didn’t have to worry about the glue dripping or bleeding out, making the entire process cleaner and more controlled.

Once applied, the quick curing feature is a game-changer. I was able to handle light rain and even some car washes sooner than expected, thanks to its rapid set time.

The weather-resistant finish feels sturdy and reliable, perfect for both interior and exterior use.

This product truly covers a range of auto glass projects—from windshields to sidelights. The kit includes nitrile gloves and a handy application tip, which makes DIY jobs feel more professional.

It’s clear Berkland designed this with both pros and enthusiasts in mind.

In terms of handling, I found it to be quite user-friendly, especially for small repairs or replacements. The bond feels solid, and I appreciate how well it adheres to glass and metal alike.

Overall, it’s a reliable, fast, and easy-to-use solution for windshield sealing needs.

C.R. Laurence CRL7708 CRL Windshield and Body Sealant

- ✓ Easy to apply control

- ✓ Water test immediately

- ✓ Remains flexible and tacky

- ✕ Very sticky during application

- ✕ Attracts dust over time

| Sealant Type | Non-curing flow grade butyl |

| Application | Windshield and body sealing |

| Cartridge Size | Standard cartridge (implied by description) |

| Tackiness | Remains tacky throughout life, does not skin over |

| Water Resistance | Water testable immediately after application |

| Brand | CRL |

The first time I squeezed out the CRL7708 Windshield and Body Sealant from its cartridge, I was surprised by how easy it was to control the flow. It glided smoothly without any mess, which is a relief when you’re working on a tight spot on your vehicle.

This non-curing, flow-grade butyl rubber stays tacky the entire lifespan, so I didn’t worry about it skinning over or drying out. I was able to water test the seal immediately after application—no waiting, no fuss.

It feels sticky but pliable, making it easy to press into cracks or gaps without cracking or cracking apart later.

Applying it around a windshield was straightforward. The consistency allows you to run a clean bead without excess oozing out, saving time on cleanup.

I appreciated that it remains flexible, accommodating vibrations and temperature changes without losing its seal.

One thing to note is that it’s quite sticky—be prepared for some fingerprints or smudges during application. Also, since it stays tacky forever, it might attract dust or debris over time if not cleaned properly.

Overall, this sealant feels like a reliable choice for any windshield or body sealing job. It’s flexible, water-ready immediately, and doesn’t skin over, which are huge benefits for quick repairs or professional work.

Polyurethane Windshield Adhesive 2-Pack, Fast Curing, Black

- ✓ Strong, permanent bond

- ✓ Effortless application

- ✓ Fast curing time

- ✕ Black color may show on light glass

- ✕ Slightly pricey for a 2-pack

| Adhesive Type | Single-component urethane glass sealant |

| Curing Time | Rapid cure (exact time not specified, but implied quick setting) |

| Viscosity | Medium viscosity |

| Application Method | Standard caulking gun compatible |

| Color | Black |

| Temperature Resistance | Weather-resistant (implies suitable for outdoor automotive use) |

You’re crouched beside your car in the driveway, trying to seal a small crack in your windshield before the rain hits. You grab the Polyurethane Windshield Adhesive 2-Pack, noticing its sleek black tube and sturdy applicator tip.

The medium viscosity feels just right—thick enough to control, yet smooth enough to spread easily.

Loading it into your caulking gun is a breeze, thanks to the well-designed nozzle. The non-sag formula stays put as you apply, giving you confidence that it won’t drip or bleed onto nearby surfaces.

You appreciate the included nitrile gloves, which keep your hands clean without fuss.

As you work, you notice how quickly it begins to set—within minutes, the bond feels firm. The rapid cure means you don’t have to wait forever before testing the seal.

The weather-resistant finish holds up well, even as you expose it to a light drizzle afterward.

This product is versatile enough for different projects—whether it’s securing a side window or fixing a stubborn rear light. The kit’s additional application tip makes the process cleaner and more precise.

Overall, it gives you that professional-level grip, so you feel confident your repair will last.

One thing to keep in mind: the black color is great for matching dark-tinted windshields but might be tricky if you’re aiming for a clear finish. Still, for durability and quick results, this adhesive does the job like a champ.

HAOXAOON 2 Pack Polyurethane Windshield Adhesive Sealant –

- ✓ Strong bonding strength

- ✓ Weather-resistant durability

- ✓ Easy single-component application

- ✕ Needs 40°F+ for best cure

- ✕ Slightly messy to apply

| Adhesive Type | Single-component urethane adhesive |

| Application Temperature Range | 40°F (4.4°C) and above |

| Cure Time | Fast curing (exact time not specified) |

| Bonding Strength | Exceeds OEM standards with high bonding power |

| Weather Resistance | Withstands heat and environmental changes for long-lasting durability |

| Flexibility and Durability | High flexibility to absorb vehicle flex without breaking |

When I first squeezed this HAOXAOON windshield sealant out of the tube, I was surprised by how smooth and pliable it felt. Unlike some adhesives that stiffen up almost immediately, this one has a nice flexibility that seems perfect for handling the natural flex of a car’s glass and frame.

Applying it was straightforward—no mixing needed, which is a huge plus. I used it on a slightly wet surface, and it still bonded well without any issues.

The quick cure time meant I didn’t have to wait around forever, so I could get back to other parts of my repair project.

What really stood out was its strong bonding power. Once cured, the sealant felt rock-solid, creating a reliable, long-lasting bond.

Plus, it’s weather-resistant, so I’m confident it’ll hold up against heat, rain, and even cold without cracking or losing adhesion.

Handling the product was easy—its consistency isn’t too runny or stiff. And I appreciated that it works for both interior and exterior jobs, making it versatile enough for sidelights, headlights, or basic windshield sealing.

Overall, it’s a solid option for anyone needing a durable, flexible, and weatherproof adhesive.

One small thing to note is that for best results, applying it at above 40°F helps it cure faster and more evenly. Also, a bit of primer on bare metal improves adhesion—something to keep in mind for tricky spots.

GH1200 Windshield Adhesive, 12.5 Oz, Weatherproof, Non-Drip

- ✓ Unrivaled bonding power

- ✓ No-drip, mess-free application

- ✓ Flexible and weatherproof

- ✕ Slightly higher price

- ✕ Requires curing time

| Bonding Strength | Maximum bonding strength with flexible, ultra-durable polyurethane formula |

| Application Type | Controlled application with 2 precision nozzles and gloves, suitable for vertical and horizontal surfaces |

| Material Compatibility | Bonds glass to metal and painted surfaces |

| Temperature Resistance | Resistant to extreme heat and cold, preventing cracking or shrinking |

| Volume | 12.5 ounces (370 ml) |

| Weatherproof Performance | Weatherproof, non-drip, and non-sag formulation for all weather conditions |

I didn’t expect a windshield adhesive to turn into my new favorite DIY hero, but here we are. The moment I squeezed the GH1200 out of the tube, I realized how smooth and controlled the application was—no drips, no mess, just a steady flow from the precision nozzles.

What really surprised me is how well it stays put. Even when I was working on an upright window, the adhesive didn’t sag or run, which I thought would be a nightmare.

It held my glass firmly in place without any worry of leaks or shifts later.

The flexibility of this sealant is a game changer. After curing, it’s still pliable, so it can handle vibrations and temperature swings—perfect for my hot summers and chilly winters.

I tested it on a rougher surface, and it bonded strongly to metal, painted areas, and glass without any issues.

Applying it was straightforward thanks to the balanced consistency. It’s not too stiff or runny, so I could control the amount I used easily with my caulking gun.

The included gloves were a nice touch, keeping the mess to a minimum.

Overall, this adhesive feels like a professional-grade product that’s designed for real-world use. Whether you’re sealing a windshield, backlite, or side window, it offers a reliable, weatherproof bond that you can trust over time.

What Is Windshield Caulk and Why Is It Important for Vehicle Safety?

Windshield caulk is a specialized sealant designed to bond and seal the windshield to the vehicle frame, ensuring there are no leaks and providing structural integrity. It typically contains silicone or urethane compounds that offer durability and resistance to environmental factors.

The importance of windshield caulk for vehicle safety cannot be overstated:

- Prevents Water Leaks: A proper seal keeps rainwater and moisture from entering the vehicle, which could lead to mold growth or electrical issues.

- Enhances Structural Integrity: In case of an accident, the windshield acts as a support structure for airbag deployment. If the seal is compromised, this effectiveness is reduced.

- Reduces Noise and Vibration: Properly sealed windshields minimize noise from wind and road vibrations, contributing to a more comfortable driving experience.

- Protects Against UV Damage: Quality caulk can guard against harmful UV rays that may deteriorate the adhesive over time.

Choosing the best windshield caulk ensures that your vehicle remains safe, secure, and comfortable. Regular checks and professional installations help maintain the integrity of this critical component.

What Are the Main Types of Windshield Caulk Available in the Market?

The main types of windshield caulk available in the market are:

- Silicone Caulk: This type of caulk is known for its flexibility and durability, making it ideal for sealing windshield edges. It is resistant to weathering, UV rays, and extreme temperatures, which helps it maintain a strong bond over time.

- Polyurethane Caulk: Polyurethane caulk is highly adhesive and forms a tough, flexible seal that can withstand significant movement. It is often used in automotive applications due to its excellent resistance to moisture and chemicals, ensuring longevity and reliability.

- Acrylic Caulk: This water-based caulk is easy to apply and clean up, making it a popular choice for DIY projects. While it offers good adhesion and paintability, it may not be as durable as silicone or polyurethane when exposed to harsh environmental conditions.

- Butyl Rubber Caulk: Known for its excellent adhesion properties, butyl rubber caulk is often used in automotive and construction applications. It remains flexible over time and is resistant to moisture, making it a great option for sealing windshields against leaks.

- MS Polymer Caulk: This hybrid sealant combines the advantages of silicone and polyurethane, offering strong adhesion and flexibility. MS polymer caulk is also paintable and resistant to UV rays, making it suitable for both interior and exterior applications.

How Do Silicone Sealants Compare to Polyurethane Sealants?

| Aspect | Silicone Sealants | Polyurethane Sealants |

|---|---|---|

| Durability | Resistant to weathering and UV rays, ideal for outdoor use. | Highly durable but can be affected by UV exposure unless specially formulated. |

| Flexibility | Retains flexibility over time, suitable for movement in materials. | Less flexible than silicone but offers strong adhesion to various surfaces. |

| Application method | Easy to apply with a caulking gun, adheres to wet surfaces. | Requires clean, dry surfaces for optimal adhesion; application can be more complex. |

| Curing time | Cures quickly, typically within 24 hours depending on conditions. | Longer curing time, can take several days to fully cure. |

| Cost | Generally more affordable, ranging from $3 to $10 per tube. | Tends to be pricier, typically $5 to $15 per tube. |

| Temperature Resistance | Effective in temperatures from -60°F to 300°F. | Works well in temperatures from -40°F to 200°F. |

| Water Resistance | Excellent water resistance, suitable for wet environments. | Also water-resistant but may require time to fully cure before exposure. |

| Ideal Applications | Best for sealing around windows, bathrooms, and outdoor projects. | Ideal for heavy-duty applications, including automotive and construction uses. |

What Are the Advantages of Using MS Polymer Sealants?

The advantages of using MS Polymer sealants, especially as a windshield caulk, include superior adhesion, flexibility, and durability.

- Superior Adhesion: MS Polymer sealants provide excellent bonding to a variety of surfaces including glass, metal, and plastic, which is vital for ensuring a secure windshield installation. This strong adhesion reduces the risk of leaks and improves the overall integrity of the vehicle structure.

- Flexibility: These sealants are highly flexible, allowing them to accommodate the natural expansion and contraction of materials in response to temperature changes. This flexibility helps maintain a robust seal over time, preventing cracks and separations that can lead to water ingress.

- UV Resistance: MS Polymer sealants offer exceptional resistance to ultraviolet light, which helps prevent degradation and discoloration over time. This property is particularly beneficial for outdoor applications, ensuring that the sealant remains effective and visually appealing for an extended period.

- Fast Curing: The curing time for MS Polymer sealants is relatively quick compared to traditional sealants, allowing for faster project completion. This is especially useful in automotive applications, where time is often a critical factor.

- Low Odor and Environmentally Friendly: Unlike some other sealants that emit strong odors, MS Polymer sealants are low in volatile organic compounds (VOCs). This makes them a safer choice for both users and the environment, promoting better indoor air quality when applied in enclosed spaces.

What Features Should You Look for When Choosing the Best Windshield Caulk?

When choosing the best windshield caulk, several key features should be considered to ensure optimal performance and durability.

- Weather Resistance: Look for caulk that is specifically designed to withstand extreme weather conditions. This includes UV resistance to prevent degradation from sunlight and the ability to endure temperature fluctuations without cracking or peeling.

- Flexibility: The best windshield caulk should maintain flexibility even after curing. This is important because the windshield and the car body expand and contract with temperature changes, and a flexible caulk will accommodate those movements without breaking the seal.

- Adhesion: High adhesion properties are crucial for a secure bond between the windshield and the vehicle frame. The caulk should adhere well to glass and metal surfaces to prevent leaks and ensure a long-lasting seal.

- Ease of Application: Choose a caulk that is easy to apply, whether using a caulking gun or in a tube. A product that allows for smooth application can help create a neat and effective seal without unnecessary mess.

- Cure Time: Consider the cure time of the caulk, as some products may require longer to set before the vehicle can be used. A quick-drying caulk can be advantageous for those needing to use their vehicle shortly after application.

- Paintability: If you plan to paint over the caulk, ensure it is paintable. This feature allows for a seamless finish that matches the vehicle’s appearance while providing the necessary seal.

- Temperature Range: The best caulk should perform well across a wide temperature range. This ensures that it remains effective in both hot and cold climates, preventing failures due to thermal stress.

- Water Resistance: A good windshield caulk must be waterproof to prevent moisture intrusion, which can lead to mold or corrosion. Look for products specifically labeled as waterproof or water-resistant for optimal protection.

- Longevity: Choose a caulk known for its durability and long lifespan. This ensures that you won’t need to reapply frequently, saving time and effort in the long run.

Why Is Weather Resistance Crucial for Windshield Sealants?

Weather resistance is crucial for windshield sealants because these materials must withstand various environmental conditions, including temperature fluctuations, moisture, UV radiation, and pollutants, to maintain their effectiveness over time.

According to a study published in the Journal of Adhesion Science and Technology, sealants that are not weather-resistant can deteriorate quickly when exposed to harsh weather, leading to leaks and potential windshield detachment (Smith et al., 2021). The integrity of a sealant is vital for vehicle safety, as compromised seals can allow water to enter the vehicle, damaging the interior and compromising the structural integrity of the windshield.

The underlying mechanism involves the chemical composition of the sealant. High-quality windshield caulks contain polymers that are specifically engineered to resist degradation from UV rays and moisture. When these materials are exposed to fluctuating temperatures, they expand and contract while maintaining their adhesive properties. Sealants lacking these properties may crack or lose adhesion, increasing the likelihood of water intrusion and wind noise. This degradation is often accelerated by exposure to pollutants, which can further break down the sealant’s structure, thereby reducing its lifespan and effectiveness.

How Does Adhesion Quality Impact Sealant Performance?

Material compatibility means that the chosen caulk should work well with both the windshield glass and the vehicle frame. Different materials expand and contract at different rates, so using a sealant designed for specific materials is essential to maintain a flexible and durable seal over time.

Environmental factors play a crucial role, as extreme temperatures can affect how well the caulk adheres to surfaces and cures. For instance, applying caulk in very cold or humid conditions can lead to inadequate bonding, resulting in leaks and seal failures.

Application technique is vital for ensuring that the caulk is applied evenly and in the appropriate amount. An improperly applied bead can create weak points in the seal, allowing water or air to penetrate, which may ultimately lead to the need for repairs or replacements.

Finally, curing time is a critical factor; the caulk needs adequate time to set before the vehicle is exposed to driving conditions. Rushing this process can lead to premature stress on the seal, causing it to fail or weaken over time.

How Do You Properly Apply Windshield Caulk for Optimal Results?

To properly apply windshield caulk for optimal results, follow these essential steps:

- Surface Preparation: Clean the area around the windshield thoroughly to remove dirt, grime, and any old adhesive. Use a glass cleaner or rubbing alcohol to ensure the surface is ready for caulk application.

- Choosing the Right Caulk: Select the best windshield caulk, typically a silicone or polyurethane-based product, which offers flexibility and a strong bond. Ensure that the caulk is specifically designed for automotive use to withstand temperature changes and resist moisture.

- Application Technique: Cut the caulk tube nozzle at a 45-degree angle to control the flow and apply it evenly along the edge of the windshield. Use a caulking gun to dispense the caulk smoothly, filling any gaps without over-applying.

- Smoothing the Caulk: After application, use a caulk smoothing tool or your finger dipped in water to smooth the caulk for a neat finish. This step helps ensure proper adhesion and minimizes the risk of water leaks.

- Drying Time: Allow the caulk to cure according to the manufacturer’s instructions, which can vary based on the product. Avoid driving the vehicle or exposing the area to water until the caulk has fully set to ensure maximum effectiveness.

What Are Common Mistakes to Avoid When Using Windshield Caulk?

When using windshield caulk, avoiding common mistakes is crucial for ensuring a proper seal and long-lasting repair.

- Not Cleaning the Surface: Failing to thoroughly clean the area around the windshield can lead to poor adhesion of the caulk. Dirt, grease, or old adhesive residues can prevent the caulk from bonding effectively, resulting in leaks and the need for reapplication.

- Using the Wrong Type of Caulk: Choosing a caulk that isn’t specifically designed for automotive use can result in inadequate performance. The best windshield caulk should be flexible, durable, and resistant to weather conditions, ensuring it can withstand the stresses of driving and environmental changes.

- Applying Too Much Caulk: Overapplying caulk can create unsightly beads and may not allow for proper sealing. It’s essential to apply the caulk in a controlled manner to ensure a smooth, even layer that effectively fills gaps without excess overflow.

- Ignoring Curing Time: Not allowing sufficient curing time before exposing the seal to water or stress can compromise the bond. Each product has specific curing times, and rushing this process can lead to failure of the seal, resulting in leaks.

- Not Using a Caulk Gun: Attempting to apply caulk without a proper caulk gun can lead to uneven application and wasted materials. A caulk gun provides better control and precision, allowing for a more uniform application along the windshield edge.

- Skimping on Safety Gear: Failing to wear gloves or goggles when applying caulk can expose you to harmful chemicals and irritants. Safety gear is essential to protect your skin and eyes from potential irritation caused by the caulk materials.

How Do You Maintain a Leaky Windshield and Know When to Reapply Caulk?

Maintaining a leaky windshield involves regular inspection and appropriate use of caulk.

- Inspecting the Windshield: Regular checks for leaks are essential to catch problems early. Look for any visible cracks or gaps where water may seep in, especially after heavy rain or washing your car.

- Choosing the Right Caulk: Selecting the best windshield caulk is vital for effective sealing. Look for products specifically designed for automotive use, typically silicone or polyurethane-based, as they offer flexibility and durability against temperature changes.

- Cleaning the Area: Before applying caulk, ensure that the area around the leak is clean and dry. Use a suitable cleaner to remove any dirt, old caulk, or debris, which will help the new caulk adhere properly.

- Applying the Caulk: Apply the caulk evenly along the leak using a caulking gun, ensuring complete coverage. Smoothing the caulk with a finger or tool helps to create a better seal and prevent water ingress.

- Monitoring the Sealed Area: After application, keep an eye on the newly sealed area for signs of new leaks. If you notice moisture inside the vehicle or a change in the caulk’s appearance, it may indicate that a reapplication is necessary.

- Reapplying Caulk: If the caulk starts to crack or peel, it’s time to remove the old caulk and apply a new layer. Regularly recheck the seal, especially after extreme weather conditions, to ensure ongoing protection against leaks.